Mechanical Division

Products for various applications

We also manufacture products for:

- Tetrapak machines for food packaging: Ti6Al4V alloy components and 316L stainless steel, materials compatible with foods and that do not cause corrosion problems.

- Textile machines: Aisi 410, 42CrMo4, S355J0, C40Pb stainless steel

- Petrochemical industry : valve bodies for the petrochemical sector in LF2, Astm 105 LF2 and Aisi 316 stainless steel

- Sports activities : ice axes for mountaineering seamless between blade and low part (block) and replacement blades in 42CrMo4, 35NiCrMo4, Ti6Al4V

- Devices for diving equipment : Ti6Al4V titanium alloy and AISI 316 stainless steel

Components for hydraulic tools

Typically manufactured in 39NiCrMo3Pb, hardened, mounted on specific tools for the compression and cutting of cables, connectors, etc.

Components for automobiles and motorcycles

Wheel hubs, platforms, cranks made of light titanium alloys (Ti6Al4V) and aluminium alloys (Al6082 and Al7075) are part of the production of F.Colombo srl.

Transmission components

The continuous development of forging methods has allowed the introduction in recent years of synchronizer rings production. These products are characterised by the finish of directly hot forged teeth, with an excellent surface appearance and the respect of very small tolerances of both shape and dimension.

They are produced in 16MnCr5, 20MnCr5, 18NiCrMo5, 16CrNi4.

The annexed pdf contains the technical characteristics of the synchronizer rings produced by F. Colombo srl.

Download PDFConnecting rods for automobiles and motorcycles

F. Colombo srl specializes in the production of connecting rods in both steel and titanium alloys. An advanced real time product and process control system combined with excellent surface finishes, with respect to the small dimension, shape and weight tolerances enable the connecting rods manufactured by FC to meet the most stringent technological and qualitative requirements of our customers. Typical materials which the components for the automotive industry are manufactured with are: Titanium alloys: Ti 6Al4V Astm B348 Ams 4928-Amst9047, Ti4Al4Mo4Sn BSTA40, etc. Steel: 34NiCrMo16, 34NiCrMo6, 30NiCrMo12, etc.

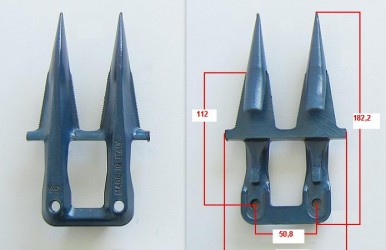

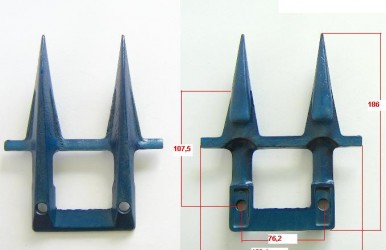

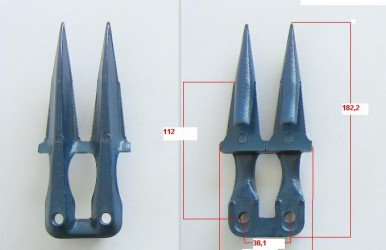

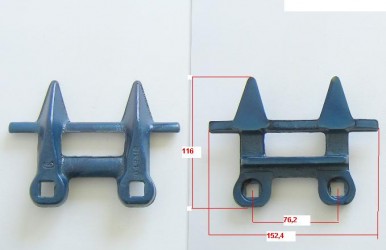

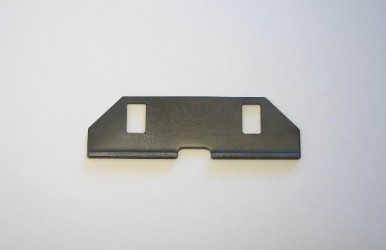

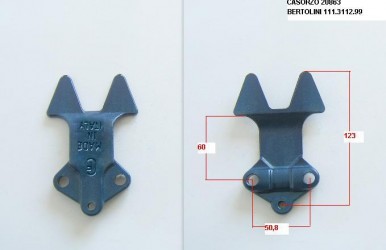

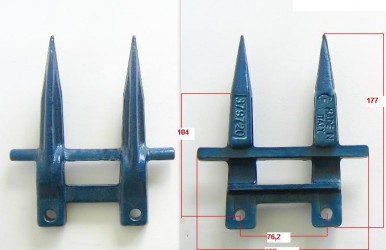

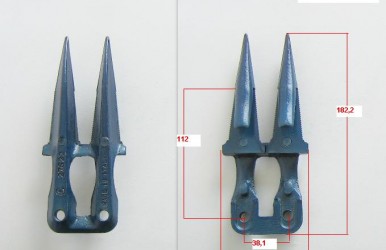

Components for agricultural machinery

Blade guard fingers for combine harvesters and mowers machines. Components made of carbon steel (C15, C50) and alloy steel (42Cr Mo 4, 46Cr2, etc.) hot-forged with the "FC" and "Made in Italy" marks. The fingers are hardening and tempering and/or induction hardening. All processing steps are performed in-house at F.Colombo srl. We use only "first choice" materials from Italy. We provide customers both the original equipment and spare parts for the following models of combine harvesters: Claas, John Deere, New Holland, Case Massey Fergusson, Bcs, etc. Our technical department can design and produce any kind of finger (blade guard) required by customers.

Download PDFComponents for closure systems

We produce closure systems for industrial vehicles and for civil and industrial buildings, forged and machined according to customer specifications and ready for installation. They are made of carbon steel (C40), stainless steel (Aisi304) and in light aluminium alloy (Al 6082).